Our System

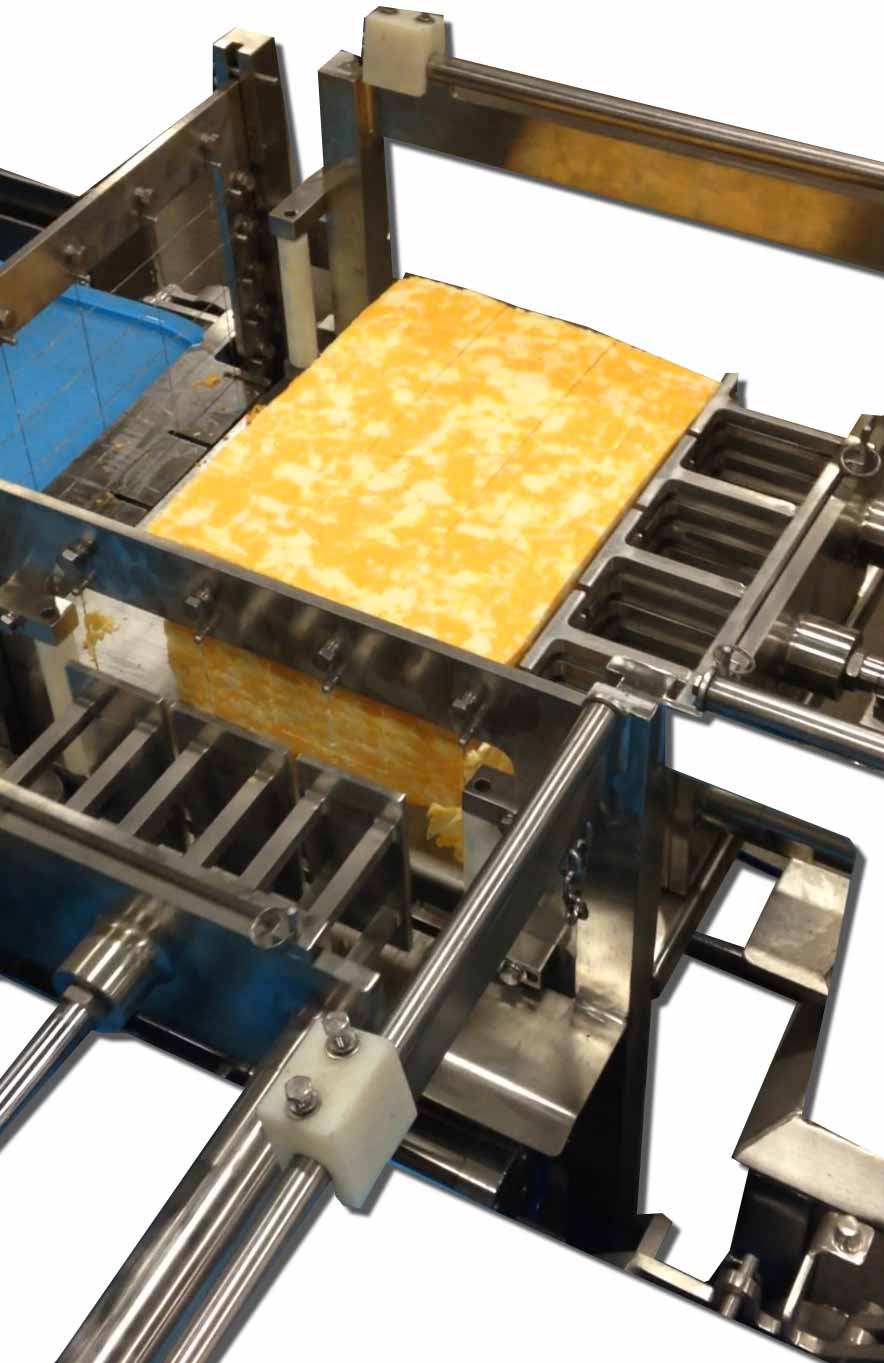

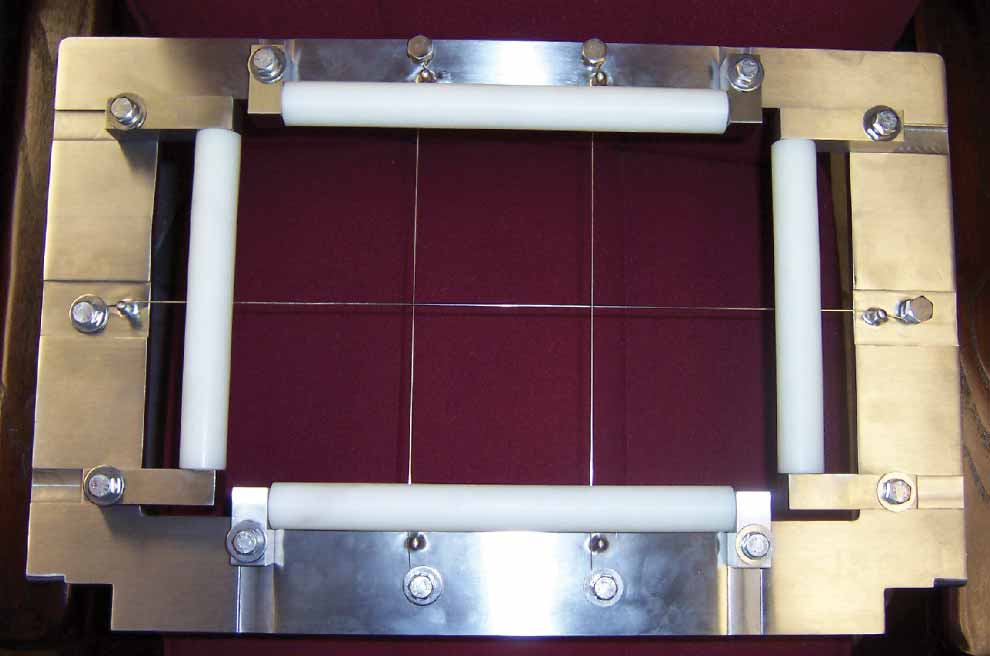

Automated Shred & Dice Systems

Our single line turn-key systems are capable of handling up to 35,000 lbs./hr. and are designed to integrate with customer specific scales and baggers.

Features

- Accept and breakdown 500 lb. barrels, 640 lb. blocks, 40 lb. or les blocks, and/or accept product directly out of the brine

- 2-way cutting or online shred cutting capabilities.

- Integrate cheese blend stations

- Salt, cellulose, natamaycin, and other inline application equipment.

- Inline weighing systems

- Operator cost savings and labor reduction